Artemis Provides Final Results of Grade Control Drilling of High-Grade Near Surface Mineralization

- 12 m grading 17.5 g/t gold (starting at 15 m)

- 12 m grading 15.3 g/t gold (starting at 3 m)

- 45 m grading 5.6 g/t gold (starting at 18 m)

- 33 m grading 10.4 g/t gold (starting at 33 m)

- 21 m grading 12.4 g/t gold (starting at 18 m)

- 39 m grading 6.5 g/t gold (starting at 21 m)

- 27 m grading 12.5 g/t gold (starting at 24 m)

Vancouver, British Columbia – June 22, 2021 – Artemis Gold Inc. (TSX-V: ARTG) (“Artemis” or the “Company”) is pleased to provide a final report on the results of its Grade Control drilling program (the “Program”) targeting the planned high- grade starter pit at the Company’s Blackwater Gold project in Central British Columbia, Canada (“Blackwater” or the “Project”).

With all of the final assay results now completed and interpreted, the Program has significantly increased confidence in the elevated gold grades within the wide, near surface mineralization in the target area earmarked for the first year of operations at Blackwater. Based on the results, the Program supports the elevated gold grades at the beginning of the mine life as outlined in the 2020 Pre-Feasibility Study for Blackwater (“Blackwater Gold Project British Columbia NI 43- 101 Technical Report on Pre-Feasibility Study” with an effective date of August 26, 2020, available on the Company’s website and on SEDAR at www.sedar.com (“2020 PFS”)).

Grade Control Drilling Program

The Program consisted of 561 holes and 33,216 m of reverse circulation (“RC”) drilling, which commenced in mid- November 2020 and concluded at the end of March 2021, one month ahead of schedule.

The Program was designed to bring the drill density from up to 50 x 50m diamond drill hole (“DDH”) spacing down to

12.5 x 12.5m spacing, generating up to 16 times the data when compared to the reserve definition drill program conducted by the Project’s previous owner, New Gold Inc. The Program targeted a zone within the first 60 m (six mining benches) from surface containing in excess of five million tonnes of high-grade ore to improve short-term mine planning at the start of production.

The other primary objectives of the Program were to:

- Optimize the grade selectivity and mine schedule for managing the ore tonnes and grade to be processed in the first year of operations;

- More accurately delineate ore and waste boundaries to mitigate dilution;

- Optimize drill and blast designs;

- Provide a larger sample size to reduce grade variability.

In production, Artemis plans a continuous grade control drilling program targeting mine blocks 9-12 months ahead of ore production to the mill to maintain this discipline throughout the life of mine operations.

Summary of Selected Grade Control Drilling Results

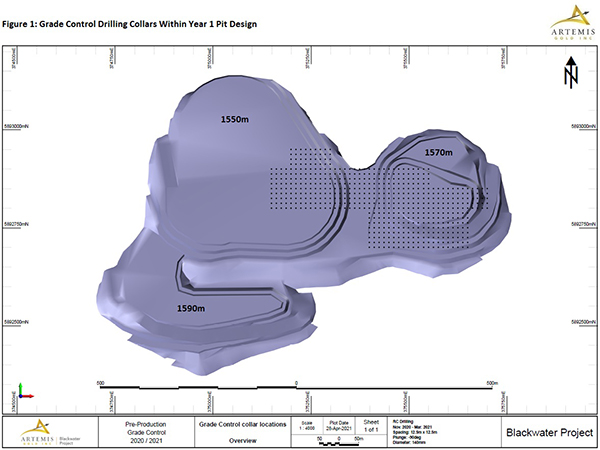

Assay results from the full Program of 10,258 samples have now been returned, confirming the planned high-grade early mining phase for Blackwater (see attached Figure 1). Selected results from the last batch of assay results from the Program are highlighted below:

Table 1: Near-Surface Intercepts from Grade Control Drilling Program1

| Hole ID* | East | North | From (m) |

To (m) | Interval | Au (g/t)** |

Ag (g/t)** |

|

| *** | BWRC00088 | 375612.5 | 5892750.0 | 21 | 39 | 18 | 9.3 | 23.8 |

| *** | BWRC00101 | 375450.0 | 5892750.0 | 24 | 39 | 15 | 6.7 | 12.8 |

| *** | BWRC00110 | 375600.0 | 5892762.5 | 18 | 63 | 45 | 5.6 | 11.1 |

| *** | incl. | 18 | 21 | 3 | 30.5 | 18.7 | ||

| *** | BWRC00119 | 375487.5 | 5892762.5 | 3 | 42 | 39 | 4.0 | 10.5 |

| *** | BWRC00122 | 375450.0 | 5892762.5 | 3 | 45 | 42 | 3.7 | 12.7 |

| *** | BWRC00147 | 375400.0 | 5892775.0 | 3 | 33 | 30 | 3.5 | 5.6 |

| *** | BWRC00157 | 375537.5 | 5892787.5 | 33 | 66 | 33 | 10.4 | 12.7 |

| *** | incl. | 45 | 51 | 6 | 39.4 | 36.3 | ||

| *** | BWRC00179 | 375575.0 | 5892800.0 | 21 | 45 | 24 | 5.9 | 9.3 |

| *** | BWRC00180 | 375562.5 | 5892800.0 | 27 | 54 | 27 | 5.8 | 9.5 |

| *** | BWRC00190 | 375437.5 | 5892800.0 | 18 | 39 | 21 | 12.4 | 12.2 |

| *** | incl. | 21 | 24 | 3 | 43.2 | 29.2 | ||

| *** | BWRC00193 | 375400.0 | 5892800.0 | 9 | 18 | 9 | 11.4 | 11.5 |

| *** | incl. | 9 | 12 | 3 | 22.5 | 11.9 | ||

| *** | BWRC00250 | 375250.0 | 5892812.5 | 6 | 60 | 54 | 3.2 | 7.1 |

| *** | BWRC00251 | 375237.5 | 5892812.5 | 21 | 60 | 39 | 6.5 | 10.8 |

| *** | incl. | 51 | 54 | 3 | 26.4 | 12.3 | ||

| *** | BWRC00259 | 375700.0 | 5892825.0 | 6 | 36 | 30 | 4.0 | 4.2 |

| *** | BWRC00265 | 375625.0 | 5892825.0 | 45 | 54 | 9 | 12.1 | 31.5 |

| *** | incl. | 48 | 51 | 3 | 21.5 | 57.2 | ||

| *** | BWRC00267 | 375600.0 | 5892825.0 | 21 | 48 | 27 | 6.8 | 14.8 |

| *** | BWRC00280 | 375437.5 | 5892825.0 | 48 | 60 | 12 | 12.6 | 15.5 |

| *** | incl. | 51 | 54 | 3 | 24.9 | 25.8 | ||

| *** | BWRC00297 | 375225.0 | 5892825.0 | 45 | 60 | 15 | 11.9 | 36.4 |

| *** | incl. | 54 | 57 | 3 | 30.8 | 72.3 | ||

| *** | BWRC00298 | 375212.5 | 5892825.0 | 42 | 60 | 18 | 48.7 | 12.0 |

| *** | incl. | 57 | 60 | 3 | 21.9 | 21.4 | ||

| *** | BWRC00319 | 375512.5 | 5892837.5 | 24 | 51 | 27 | 12.5 | 16.7 |

| *** | incl. | 39 | 42 | 3 | 58.5 | 54.3 | ||

| *** | BWRC00344 | 375200.0 | 5892837.5 | 33 | 57 | 24 | 7.9 | 6.3 |

| *** | incl. | 45 | 48 | 3 | 21.2 | 15.1 | ||

| *** | BWRC00357 | 375600.0 | 5892850.0 | 30 | 42 | 12 | 9.9 | 68.7 |

| *** | BWRC00389 | 375200.0 | 5892850.0 | 45 | 57 | 12 | 13.8 | 12.2 |

| *** | incl. | 51 | 54 | 3 | 27.5 | 13.9 | ||

| BWRC00435 | 375450.0 | 5892875.0 | 3 | 15 | 12 | 15.3 | 24.6 | |

| incl. | 6 | 9 | 3 | 50.7 | 81.3 | |||

| BWRC00463 | 375512.5 | 5892887.5 | 33 | 57 | 24 | 5.7 | 10.2 | |

| BWRC00520 | 375212.5 | 5892900.0 | 24 | 54 | 30 | 3.5 | 13.0 | |

| BWRC00532 | 375225.0 | 5892912.5 | 21 | 54 | 33 | 3.7 | 8.5 | |

| BWRC00538 | 375262.5 | 5892925.0 | 15 | 27 | 12 | 17.5 | 25.8 | |

| incl. | 18 | 24 | 6 | 29.4 | 43.0 |

* All holes were drilled with a dip of -90º (vertical). Drill hole intercepts reflect minimum 70% of the true widths of the orebody. Only intercepts greater than 9 m of length and width x grade greater than 100 g–m of gold are reflected in this news release.

** Assay results are based on the leached Au and Ag after 5-hour LeachWELLTM accelerated leach, and exclude Au and Ag remaining in residue solids.

***Previously released grade control intercepts

1 Refer to notes 1, 2, and 3 within the section entitled ”Technical Disclosure” at the end of this press release

The LeachWELLTM assay method was selected to increase the sample size from a more standard 50g to 1,000g sample, which reduces variability and increases repeatability of assay results. Additionally, the LeachWELLTM method increases the understanding of leachability of the orebody with the information feeding directly into the process design. Extensive duplicate analyses highlight excellent LeachWELLTM repeatability of assay results and recoverable gold and silver.

Of the total samples assayed, 1,207 samples were also assayed for residue gold and silver concentration in the LeachWELLTM residues, resulting in a calculated overall recovery of 96.5% for gold and 69.3% for silver.

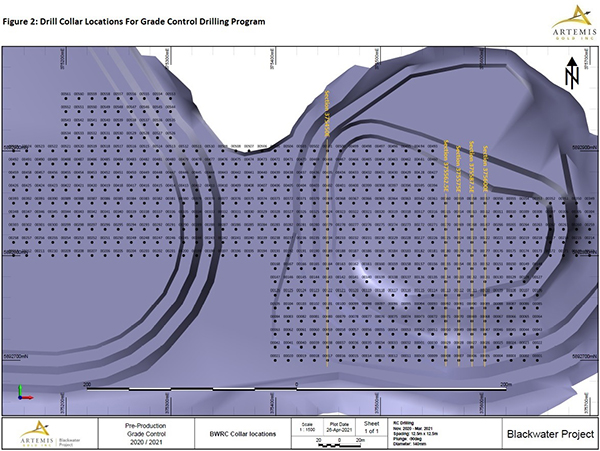

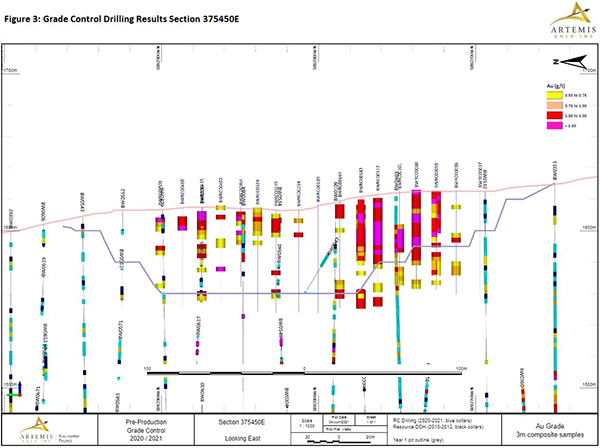

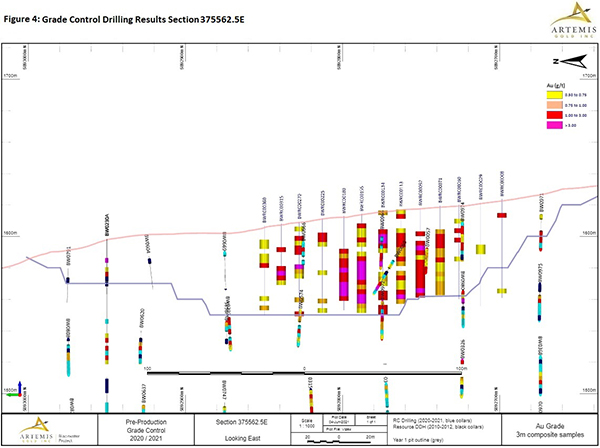

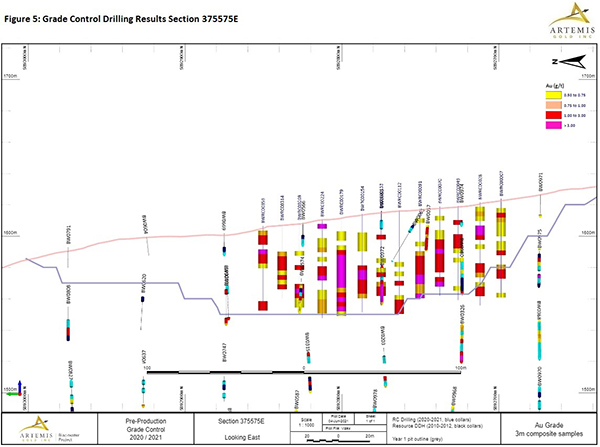

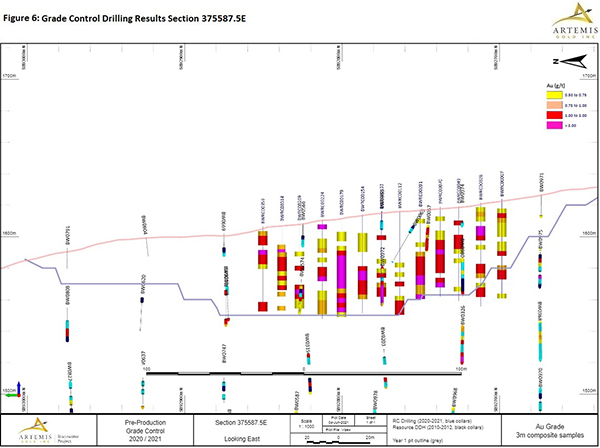

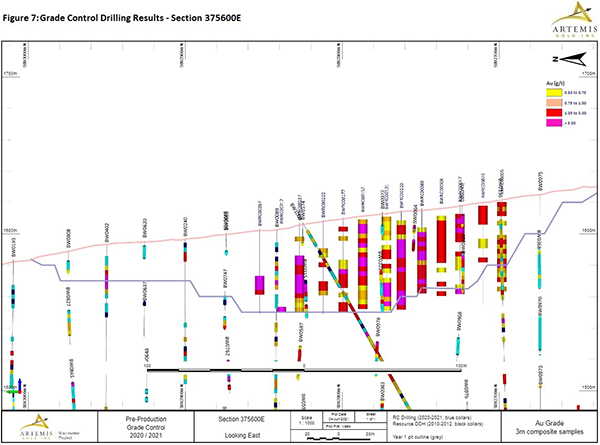

Including the previously released results, the Program has also confirmed excellent continuity of mineralization, as illustrated in the sections provided in Figures 3-7. The location of these sections is provided in Figure 2.

Steven Dean, Chairman and CEO, commented “The final results of the grade control drilling program continue to indicate the potential for more tonnage and more contained ounces within the high-grade starter zone, with the potential to reduce the strip ratio at the beginning of the mine life. This program confirms the strong continuity of high-grade mineralization at the start of the mine life and provides a higher confidence level in the Phase 1 mining schedule outlined in the Company’s 2020 Pre-Feasibility Study, further derisking the start up of operations.”

Technical Disclosure

Drill sampling consisted of reverse circulation drill cuttings being collected at a drill mounted Metzke rotating cone splitter by Artemis personnel on 3 m intervals. Samples were placed into bags and further split at the Blackwater sampling facility to ~3 kg sample size using a jones riffle splitter. Samples were tagged with barcodes, placed in a sample crate and a laboratory dispatch form was completed. Samples were stored in a secure location prior to shipping. Chain-of-custody procedures consisted of filling out sample submittal forms that were sent to the laboratory with sample shipments to make certain that all samples were received by the laboratory.

Sample preparation and analysis were performed by SGS Canada Inc. (“SGS”), located in Burnaby, British Columbia, Canada. SGS holds ISO/IEC accreditation for selected sample preparation and analytical techniques and is independent of the Company. Sample preparation consisted of drying, crushing and pulverizing to 75% passing 75 µm. Gold and silver analyses were performed using a 5-hour 1,000 g LeachWELLTM method with an inductively coupled plasma mass spectrometry finish (ICP-MS).

The representativeness of the LeachWELLTM analytical technique to a mineral deposit is dependent on the leaching characteristics of the material submitted. As no certified standard reference material had been prepared from the same material that was to be leached, no standard reference materials were inserted in the grade control sample stream to directly monitor analytical precision. Precision checks consisted of comparisons to results from split samples using 50 g fire assay methods, comparison of data to existing diamond drill holes and review of SGS laboratory standards. Additionally, LeachWELLTM tails solids were consistently checked for non leachable gold and silver using 50 g fire assay for gold and 2 g 4-acid digestion for silver. The Company randomly inserted blank and duplicate samples into the sample stream as part of the quality assurance and quality control (QA/QC) monitoring for the Program at an insertion rate of

~14%. These samples had closely monitored contamination, splitter functionality and analytical repeatability, respectively.

Mr. Klaus Popelka (Qualified Person) reviewed the available Program data, and considers that the sample preparation, security, and analytical procedures are acceptable. There are no drilling, sampling or recovery factors known to the QP that could materially impact the accuracy and reliability of the results presented in this news release.

Qualified Persons

Klaus Popelka, P. Geo., Manager Resource Geology for Artemis, and a QP as defined by National Instrument 43-101, has reviewed, and approved the scientific and technical information in this news release.

ARTEMIS GOLD INC.

On behalf of the Board of Directors

“Steven Dean”

Chairman and Chief Executive Officer

+1 604 558 1107

For further information:

Nick Campbell, VP Capital Markets, +1 (604) 558-1107.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Cautionary Note Regarding Forward-Looking Information

This news release contains certain “forward looking statements” and certain “forward-looking information” as defined under applicable Canadian and U.S. securities laws. Forward-looking statements and information can generally be identified by the use of forward-looking terminology such as “may”, “will”, “expect”, “intend”, “estimate”, “anticipate”, “believe”, “continue”, “plans”, “potential” or similar terminology. Forward-looking statements and information are not historical facts, are made as of the date of this news release, and include, but are not limited to, statements regarding the Program; the planned next steps of the Company with respect to the Project, including permitting, drilling programs, awarding EPC Contracts, arranging debt and equity financing, consultation with indigenous groups and work on the Definitive Feasibility Study; and other plans and expectations of the Company with respect to the Project. These forward- looking statements involve numerous risks and uncertainties and actual results may vary. Important factors that may cause actual results to vary include without limitation, risks related to the ability of the Company to accomplish its plans and objectives with respect to the development of the Project within the expected timing or at all, the timing and receipt of certain required approvals, changes in commodity prices, changes in interest and currency exchange rates, risks inherent in exploration and development activities, changes in development or mining plans due to changes in logistical, technical or other factors, unanticipated operational difficulties (including failure of plant, equipment or processes to operate in accordance with specifications, cost escalation, unavailability of materials, equipment or third party contractors, delays in the receipt of government approvals, industrial disturbances, job action, and unanticipated events related to heath, safety and environmental matters), the COVID-19 pandemic, political risk, social unrest, changes in general economic conditions or conditions in the financial markets, and other risks related to the ability of the Company to proceed with its plans for the Project and other risks set out in the Company’s most recent MD&A. In making the forward-looking statements in this news release, the Company has applied several material assumptions, including without limitation, the assumptions that: (1) market fundamentals will result in sustained mineral demand and prices; (2) the receipt of any necessary approvals and consents in connection with the development of the Project; (3) the availability of financing on suitable terms for the development, construction and continued operation of the Project; (4) sustained commodity prices such that the Project remains economically viable; and (5) that the COVID-19 pandemic and restrictions related thereto will not materially impact the Company or prevent the Company from operating its business as planned. The actual results or performance by the Company could differ materially from those expressed in, or implied by, any forward-looking statements. Accordingly, no assurances can be given that any of the events anticipated by the forward-looking statements will transpire or occur, or if any of them do so, what impact they will have on the results of operations or financial condition of the Company. Except as required by law, the Company is under no obligation, and expressly disclaim any obligation, to update, alter or otherwise revise any forward-looking statement, whether written or oral, that may be made from time to time, whether as a result of new information, future events or otherwise, except as may be required under applicable securities laws.